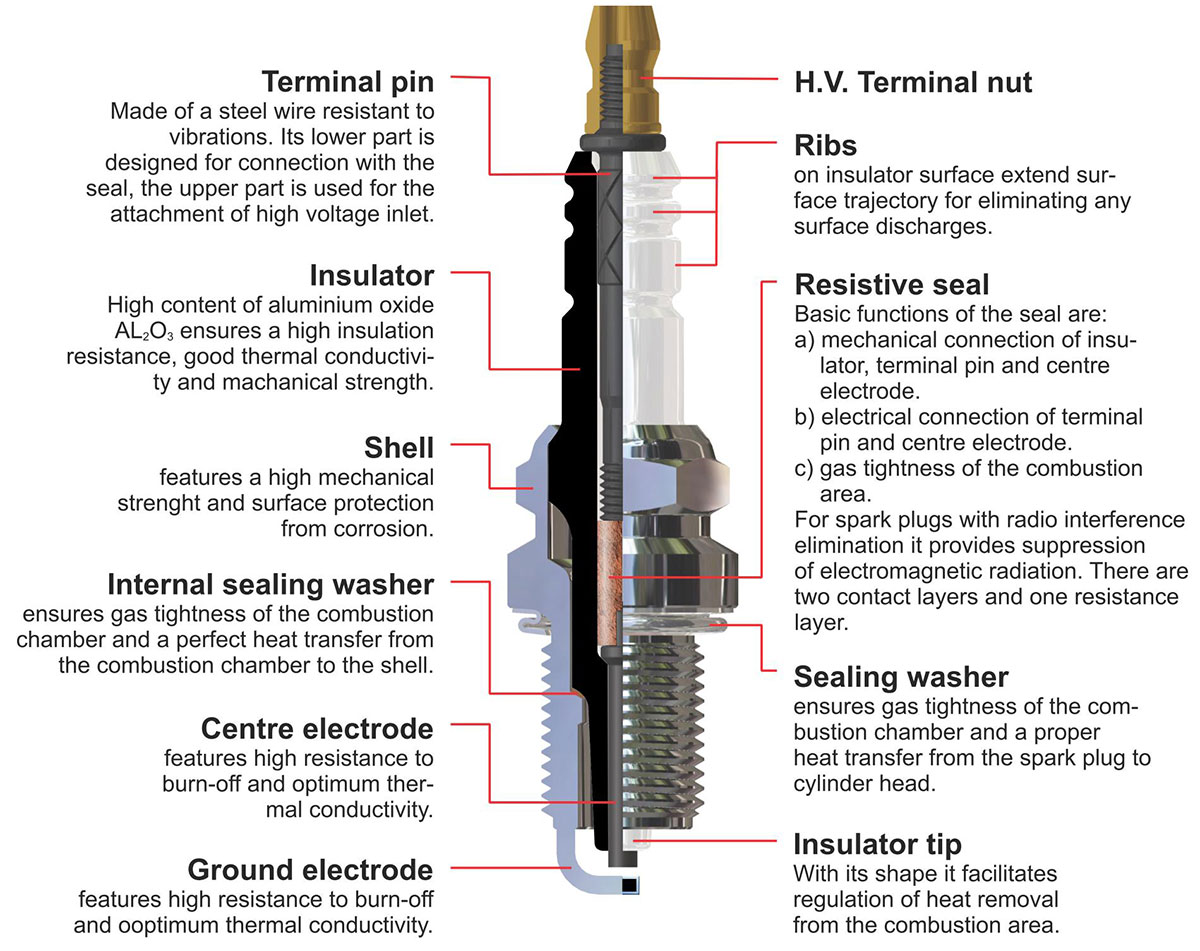

SPARK PLUG CONSTRUCTION

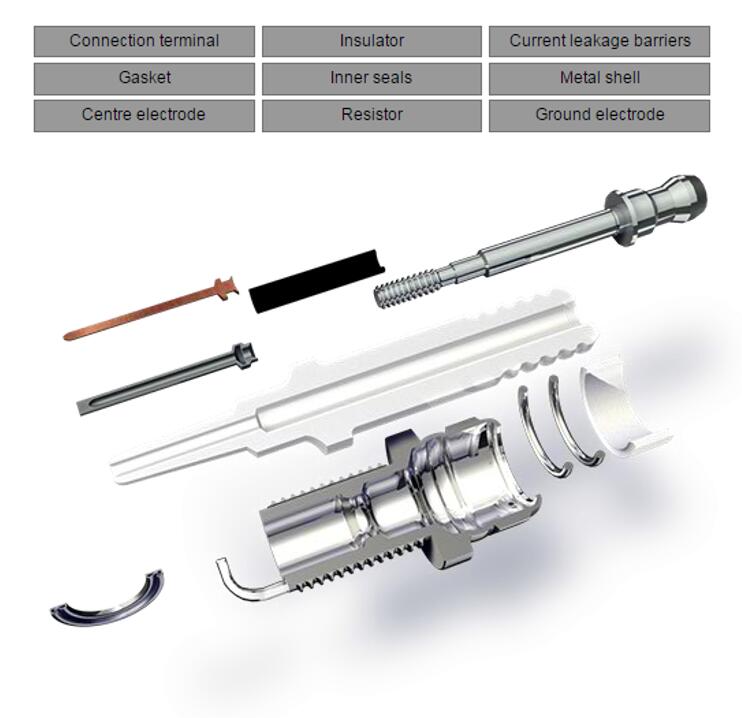

Hot Riveting Production Technology Spark plug Equal to BOSCH Spark Plug

Cold Seal Riveting Production Technology Spark Plug Equal to NGK Spark Plug

INSULATOR

The most important component of the spark plug

1) Electrically separates the electrodes

2) Regulates heat transfer from the combustion chamber

3) Fixes the center electrode and terminal pin

4) Resists chemical substances in the combustion chamber

LJK TIP

LJK makes insulators from high quality ceramic materials with a high content of Al2O3 (Almatis GE Alumina) and high insulation strength.

CENTer ELECTRODE

Fundamentally influences the lifetime of the spark plug

1) Ensures low wear

2) Low voltage requirement from the ignition system

3) High thermal conductivity makes it possible to use a longer insulator tip at same heat range

4) Resistant to thermal and chemical influences in the combustion chamber

LJK TIP

LJK center electrodes are made from special alloys(Nickel and Copper insert) and precious metals(Iridium and Platinum) that ensure the required optimal properties

TERMINAL PIN

Provides high-voltage connectivity

1) Different types of termination as required by the vehicle in question

2) Firmly anchored in the resistive seal

3) Protected against corrosion

LJK TIP

LJK manufactures a range of terminal pins with termination for the cable nut, as well as for direct connections to the high-voltage supply from the ignition system.

RESISTIVE SEAL

Ensures the mechanical connection of the insulator, terminal pin and center electrode

1) Electrical and thermal connection of the center electrode and terminal pin

2) Gas tightness of the combustion area

3) Suppresses electromagnetic radiation

LJK TIP

LJK has developed a high quality resistive seal, which suppresses electromagnetic radiation and simultaneously resists the highest vibrations. The resistor value was controlled by 3-9kom.

TERMINAL NUT

Allows alternative connection of high voltage

1) Various types of materials according to the type of spark plug used

2) Possibility of fixture against loosening

LJK TIP

LJK provides various types of connections according to customer’s requirements. From secured steel nuts for the engines with high vibrations to the nuts made of light alloys or universal connection for most of the users.

INNER SEALS

The inner seals create a gas-tight connection between insulator and metal housing. The seal is made from a talcum ring enclosed between two additional stainless steel sealing rings. During production of the spark plug the talc ring is compacted tightly ensuring a perfect gas tight seal.

LJK TIP

LJK provide Cold Seal Riveting Spark plug equal to NGK technology, the inner seal is the important key component to ensure Insulator riveting with Metal shell.

Metal SHELL

Ensures the installation of the spark plug into the cylinder head.

1) Standard thread dimensions

2) Electrothermal assembly of the shell-insulator creates permanent pre-stress for perfect transmission of heat.

3) Corrosion resistant surface finish

4) High tear resistance

LJK TIP

LJK makes the shell by the cold moulding method. High strength of the shell is secured by uninterrupted flow of the material fibres.

GROUND ELECTRODE

Fundamentally influences the service life of the spark plug

1) Ensures low wear

2) Low voltage requirement from the ignition system

3) Resistant to thermal and chemical influences in combustion chamber

4) By suitable design, it suppresses the quenching effect during cold starts

LJK TIP

LJK makes spark plugs with ground electrodes from different materials including composite design. Convenient shaping helps to reduce the requirement for voltage supplied by the ignition system and unique suppression of the quenching effect during cold starts.

INTERNAL SEALING WASHER

Ensures gas tightness of the spark plug

1) Transmits heat from the insulator tip to the shell

2) Prevents leak of gases from the combustion chamber into the spark plug

3) Compensates and distributes the tension from pres-tress during electrothermal assembly

LJK TIP

LJK utilises its long-term experience with electro-thermal assembly technology and knowledge of thermal flows between the spark plug and engine parts.

SEALING WASHER

Ensures gas tightness between the spark plug and cylinder head

1) Reliable sealing of the combustion chamber

2) Various shapes for different contact surfaces

3) Non-fall off design

4) Anticorrosion surface finish

LJK TIP

LJK adapts the sealing washer to the contact surface requirements of individual engines.

INSULATOR TIP

The most important part of the insulator

1) The length of the tip determines the heat range of the spark plugs

2) The shape of the tip end of the insulator changes the build-up rate to working temperature

3) The shape of the tip affects the mechanical strength of the insulator

4) The thermal conductivity of the insulator tip significantly affects the balance of heat intake and transfer

5) Vibration resistance is above a given competitor standard

LJK TIP

Thanks to the perfect shape of the insulator tip, the LJK spark plugs have the desired characteristics in terms of thermal properties, tensile strength and insulation resistance in the very aggressive environment of the combustion chamber.